Custom 건축 바닥재 Manufacturers

다양한 장식 스타일을 충족하는 다양한 재료 및 스타일 옵션

다양한 장식 스타일을 충족하는 다양한 재료 및 스타일 옵션

PVC 천장 패널은 내구성, 낮은 유지 관리 및 미적 다양성으로 인해 현대 건축에서 인기 있는 선택이 되었습니다. 그러나 잘못 설치하면 뒤틀림, 틈 또는 조기 손상이 발생할 수 있습니다. 지속적인 성능을 달성하려면 올바른 설치 기술, 준비 및 환경 고려 사항을 이해하는 것이 필수적입니다. PVC 천장 패널 및 일반적인 뒤틀림 문제 이해 PVC 천장판은 경량, 방수 소재로 주거, 상업, 산업 공간에 널리 사용됩니다. 뒤틀림은 일반적으로 패널이 구부러지거나 구부러지거나 비틀릴 때 발생합니다. 수분 흡수, 온도 변...

View MoreSPC 벽면 패널은 내구성, 내수성 및 낮은 유지 관리로 인해 현대적인 인테리어에 널리 사용됩니다. 그러나, SPC 벽면 패널 절단 및 성형 손상을 방지하려면 재료에 대한 정밀성과 이해가 필요합니다. 부적절하게 취급하면 가장자리가 부서지거나 표면이 고르지 않거나 구조적 약점이 발생할 수 있습니다. 이해 SPC 벽면 SPC 벽면 패널은 석재-플라스틱 복합재로 강화된 견고한 비닐 패널의 일종으로 안정성과 내습성이 향상되었습니다. 전통적인 목재 패널과 달리 SPC 벽 패널은 밀도가 높고 단단하며 뒤...

View More대나무 목재 섬유 벽 패널은 친환경 특성, 내구성 및 미적 매력으로 인해 현대적인 내부 및 외부 디자인에서 널리 주목을 받고 있습니다. 올바르게 설치하면 긴 수명이 보장될 뿐만 아니라 패널의 구조적 무결성과 시각적 매력도 유지됩니다. 대나무 목재 섬유 벽 패널 이해 설치 과정을 논의하기 전에, 설치 과정의 특성을 이해하는 것이 필수적입니다. 대나무 나무 섬유 벽면 . 이 패널은 천연 대나무 섬유로 구성되며 종종 환경적으로 안전한 접착제와 결합되어 조밀하고 안정적인 재료를 만듭니다. 패널은 뒤...

View MoreAs global awareness of sustainability grows, the architectural flooring industry is undergoing a green revolution. With nearly 20 years of expertise in PVC building materials, Haining Halong PVC Ceiling Factory and its affiliated factories (such as Guangxi PVC Wall Panel Factory and Indonesia PVC Wall Panel Factory) are committed to driving innovation in eco-friendly Architectural Flooring.

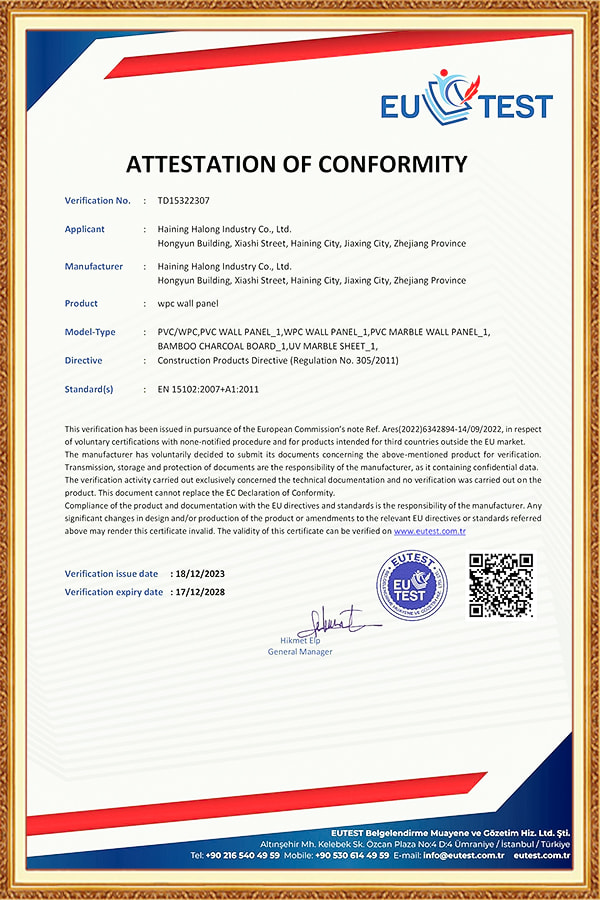

The increasing demand from consumers and the construction industry for low-carbon, recyclable materials has made products like SPC (Stone Plastic Composite) flooring and WPC (Wood Plastic Composite) decking mainstream. Our SPC Flooring and WPC Decking series incorporate sustainable materials such as recycled stone powder and plant fibers, offering waterproof and wear-resistant properties while meeting international green building certifications (e.g., LEED).

Through eco-friendly PVC lamination technology developed by Haining Longtime Film Factory, we reduce energy consumption and VOC emissions during production. Additionally, localized manufacturing in our Vietnam and Indonesia factories minimizes transportation-related carbon footprints, aligning with global sustainable supply chain trends.

The future of Architectural Flooring will focus on "closed-loop design"—products that are detachable and recyclable. We are exploring recycling solutions for PVC Ceiling Panels and WPC Wall Panels, such as converting waste materials into new boards through hot-pressing technology to reduce resource waste.

Although the cost of sustainable flooring remains higher than traditional options, policy incentives (e.g., China’s "Dual Carbon" goals) and growing consumer awareness are accelerating market adoption. With annual sales exceeding $35 million, our economies of scale help clients access high-performance green flooring at competitive prices.

Halong Group continues to advance Architectural Flooring toward a more sustainable future through material innovation and global expansion. For more details on our SPC/WPC flooring solutions, feel free to contact us.

With nearly two decades of experience in the building materials industry, our company has grown from a specialized PVC ceiling and wall panel manufacturer to a comprehensive supplier of high-quality architectural flooring solutions. Since our establishment in 2005, we have expanded our operations to include five major production facilities across China and Southeast Asia, allowing us to serve global markets with efficient manufacturing and distribution capabilities.

Our manufacturing network includes the Haining Halong PVC Ceiling Factory in Zhejiang province, which serves as our flagship production base for PVC-based building materials. The Guangxi PVC Wall Panel Factory specializes in large-format panel production, while our Southeast Asian facilities in Indonesia and Vietnam provide strategic advantages for serving international markets with reduced logistics costs and faster delivery times.

The Haining Longtime Film Factory plays a crucial role in our vertical integration strategy, producing high-quality lamination films and hot stamping foils that enhance the durability and aesthetic appeal of our flooring products. This complete in-house production chain ensures strict quality control from raw materials to finished goods.

Our product development focuses on three main categories of architectural flooring solutions. For residential applications, we offer a range of SPC flooring options that combine the natural look of wood with superior water resistance and dimensional stability. These products are particularly suitable for high-moisture environments and areas requiring frequent cleaning.

Commercial projects benefit from our heavy-duty PVC and WPC flooring systems, designed to withstand high foot traffic while maintaining their appearance over time. Our technical team works closely with architects and contractors to develop customized solutions for specific project requirements, including specialized finishes and enhanced slip resistance.

For outdoor applications, our WPC decking products provide an eco-friendly alternative to traditional wood decking, offering superior resistance to weathering, insects, and rot. These products are increasingly popular for balcony, terrace, and poolside installations in both residential and hospitality projects.

Each of our manufacturing facilities operates under a rigorous quality management system, with dedicated teams overseeing every stage of production from material selection to final inspection. We conduct regular testing of our products to ensure they meet or exceed international standards for dimensional stability, wear resistance, and environmental safety.

Our research and development department works continuously to improve product performance and develop new solutions. Recent innovations include enhanced surface textures that more accurately replicate natural materials, improved locking systems for easier installation, and advanced UV-resistant formulations for outdoor products.

As part of our commitment to environmental responsibility, we have implemented several initiatives to reduce the ecological impact of our manufacturing processes. These include energy-efficient production equipment, water recycling systems, and waste reduction programs that allow us to reuse production byproducts.

Many of our flooring products incorporate recycled materials without compromising quality or performance. Our SPC flooring, for example, contains a high percentage of natural limestone powder, while our WPC products utilize wood fibers from sustainable sources. These material choices help reduce our environmental footprint while providing customers with eco-conscious building solutions.

With annual sales exceeding 35 million USD, our company has established a strong presence in both domestic and international markets. We maintain long-term relationships with distributors and contractors across multiple continents, supported by our ability to provide consistent product quality and reliable delivery schedules.

Our customer service team offers comprehensive support throughout the project lifecycle, from initial product selection and specification assistance to after-sales technical support. We provide detailed installation guides, material specifications, and maintenance recommendations to ensure optimal performance of our flooring products.

Looking ahead, we continue to invest in expanding our production capacity and developing new product lines to meet evolving market demands. By combining our manufacturing expertise with a customer-focused approach, we aim to strengthen our position as a trusted partner for architectural flooring solutions worldwide.